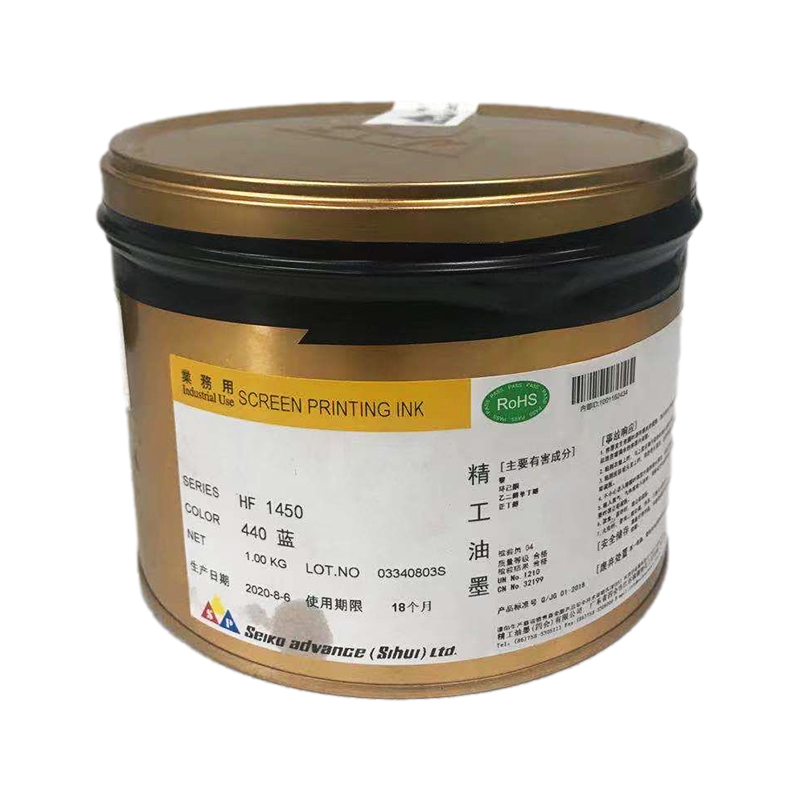

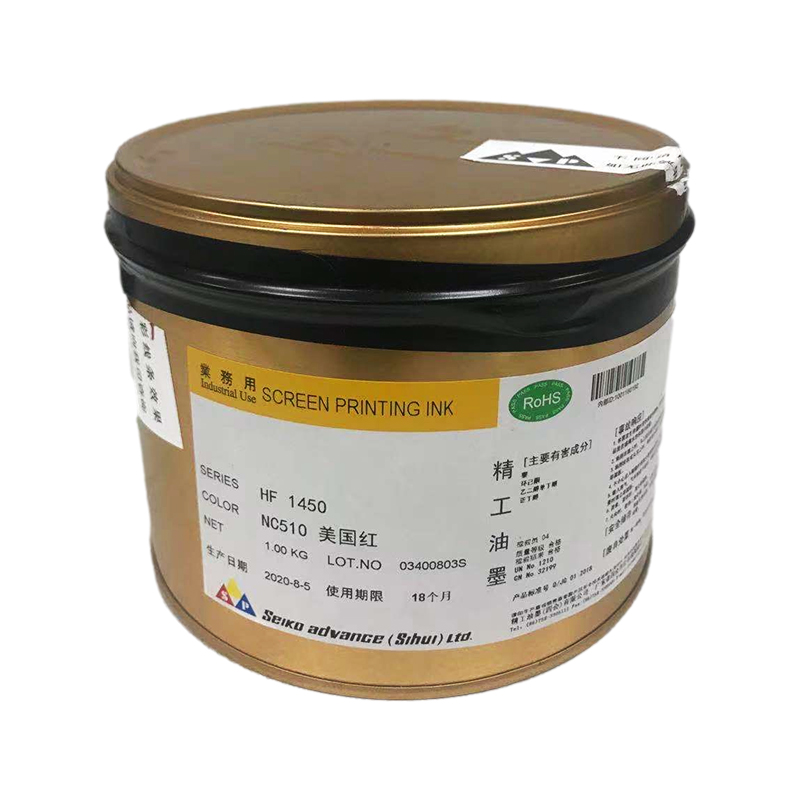

HF 1450 Series

- Product details

- Service hotline:0769 - 87727302

Specifications

Polyester/melamine two-component heated hard type

Characteristic

Excellent leveling, secondary processing (stamping, bending, extrusion processing), and solvent resistance.

Hardener

- Standard hardener: HF 1450 hardener

- Mixing ratio:

- Solid color: Hardening agent=80:20

- Transparent color: Hardening agent=75:25

- Concentrated 120: Hardening agent=85:15

Diluent

- Standard diluent: T-980/T-990

- Mixing ratio:

- (Inks + Hardener): Diluent=100:10-20

Polyester or nylon 200-420 mesh screen is recommended for screen printing.

Dry

Baking conditions: 150 ℃ for 30 minutes

Other

- ・In order to adjust the hardening time, the HF 1450 series has added catalysts (to promote hardening), but the contained catalysts may experience a decrease in hardenability due to the influence of air or prolonged storage time. If this situation occurs, about 1% catalyst H can be added to restore its performance. In addition, please verify whether the performance of inks stored for a long time has changed before use.

- ・When used for glass printing, please add CARE73N (2% -5%) to the inks to improve adhesion and water resistance.

Previous item:HF MS7 Series

Next item:HF SG460 Ultra Late Drying (F) NS Series