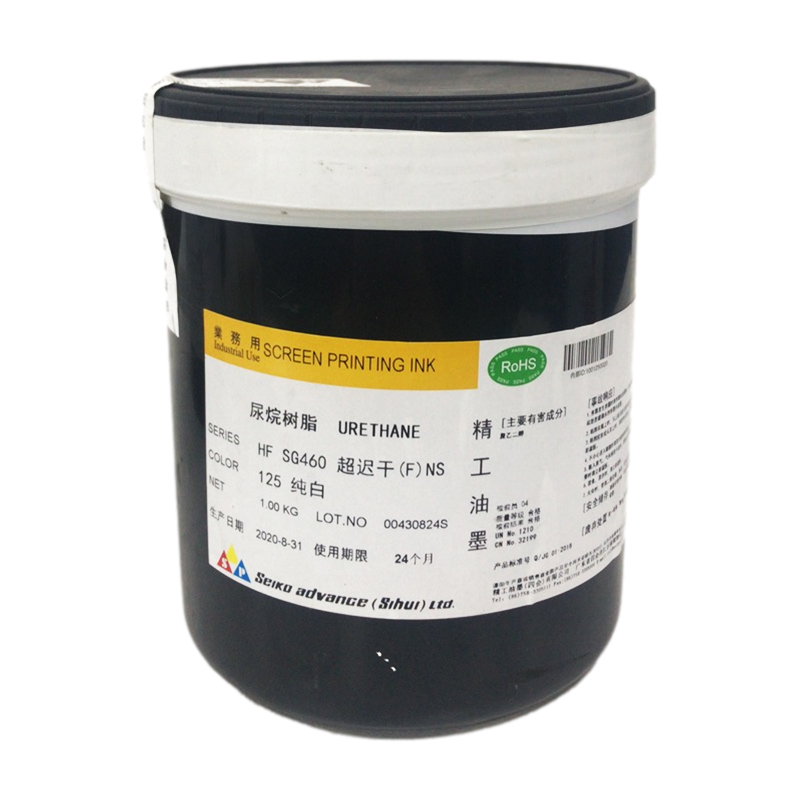

HF SG460 Ultra Late Drying (F) NS Series

- Product details

- Service hotline:0769 - 87727302

Inks type

urethane resin

3-component isocyanate hardening type

Use to

Suitable for glass and various hardened materials.

Characteristic

Excellent glossiness.

Excellent weather resistance, acid resistance, alkali resistance, solvent resistance, water resistance, friction resistance, etc.

Diluting solvent

- Standard solvent T-680 (various hardened materials)

- Standard solution T-980 (glass)

Hardening agent mixing ratio

- Mixing ratio inks: hardener=80:20~100:20 (710 black)

- *The inks mixed with hardener will become gelatinous due to chemical reactions when left at room temperature for 2-3 hours, and its physical properties will decrease, making it unsuitable for reuse.

- *When printing on glass materials, adding 3% Care-73 can improve adhesion and moisture resistance.

- *The less the amount of hardener mixed, the worse the adhesive resistance, but the better the concealment and workability. Please choose the most suitable mixing ratio for use.

Plate washing

T-39 T-41

It is recommended to use polyester or nylon screen printing with a mesh size of 200-460 for screen printing

Dry

Room temperature 80 ℃ x 50-60 minutes: Various materials that have undergone hardening treatment

Baking at 150 ℃ x 30-50 minutes: glass

Other

- ・The HF SG460 ultra late drying (F) NS series is highly sensitive to humidity. Please use it as soon as possible after opening the can.

Physical Property Test Results of HF SG460 Ultra Late Drying (F) NS Concentrated 710 Black

- Printing conditions

- Main agent HF SG460 ultra late drying (F) NS concentrated 710 black hardener D hardener

- Mix ratio 80:20

- Solvent T-98010% Material Reinforced Glass

- Mesh polyester 270 mesh

- Dry at 60 ℃ × 60 minutes+7 days at room temperature (for cyclic testing, 2 days at room temperature can be used for testing)

Testing methods and results

| Project | Method | Evaluate | Result |

| Adhesiveness | Cross cut at 1mm intervals and use tape for peeling test | No peel off | Qualified |

| Hardness | According to the pencil hardness tester, 45 ° × 750g | No obvious traces | 2H qualified |

| Cold and hot cycle resistance test | -20 ℃ × 30 minutes → 80 ℃ × 30 points are divided into one cycle, and this condition is repeated 10 times. After the end of the cycle, cross cut at 1mm intervals and use tape for peeling test | No change in appearance, no detachment | Qualified |

| Alcohol resistance | Wrap 500g of the French code with gauze, which contains grade 1 methanol and rub back and forth 50 times | Colorless transfer on gauze, no peeling after back and forth wiping | Qualified |

| rub resistance | Wrap 500g of French code with gauze and wipe back and forth 50 times | Wipe back and forth without any detachment | Qualified |

| Boiling resistance | After immersing in boiling water for 3 hours, let it stand at room temperature for more than 2 hours, cross cut at 1mm intervals, and then use tape for peeling test | No change in appearance, no detachment | Qualified |

Previous item:HF 1450 Series

Next item:HF MOL Series