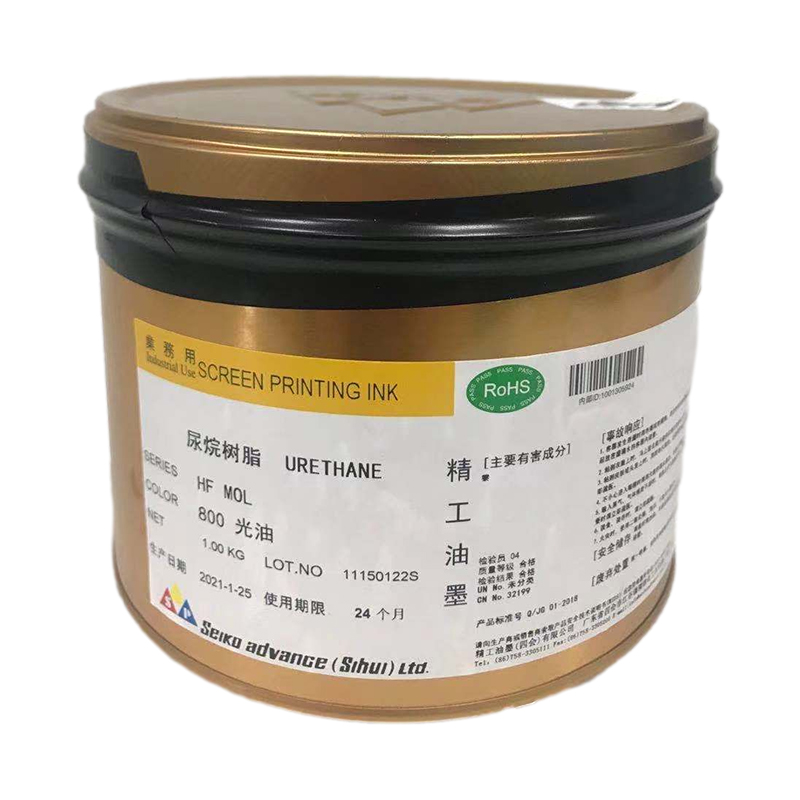

- Product details

- Service hotline:0769 - 87727302

Typology

Polyester resin, two-component hardening inks

Use to

The processed PET and polyurethane sheets have good adhesion. Excellent flexibility suitable for injection molding.

Characteristic

Form a glossy, smooth, and soft film layer with excellent softness.

Diluting solvent

- Standard solvent T-910

- Delayed drying solvent T-980

Hardening agent mixing ratio

Using hardener:

D hardening agent

Mixing ratio inks: hardener=100:10

The mixed inks is easy to appear gel when it is placed at room temperature for about 6 hours, and its physical properties will decline and become worse.

Wash solvent

T-31

It is recommended to use polyester or nylon with a mesh size of 200-300.

Dry

Heating at 80 ℃ for 30 minutes

Other

- ・D hardener is very sensitive to moisture, please use it as soon as possible after opening the can.

- ・The standard color names for the HF MOL series are as follows:

| 120 White | 207 Transparent yellow |

| 200 Light yellow | 208 Transparent yellow |

| 265 OrangeRed | 209 Yellow |

| 400 Light blue | 456 Transparent blue |

| 440 Blue | 498 Transparent purple |

| 495 Purple | 513 Transparent Red |

| 500 Flame | 538 Transparent Crimson |

| 510 American red | 586 Transparent magenta |

| 550 Ruby | 765 Transparent black |

| 580 Magenta | |

| 710 Black | |

| 800 Gloss oil | |

| 850 Dot gloss |

Regarding the colors 210 lemon yellow, 220 medium yellow, 304 transparent green, 320 light green, 350 green, and 460 sky blue, customers are requested to mix and match them themselves or have our company handle the color matching. However, the resulting color may differ from the standard color, as there are limits to the color's quality. Please understand.

Previous item:HF SG460 Ultra Late Drying (F) NS Series

Next item:1350/HF 1350 Series