The surface of the screen that has undergone sub micron level trimming can reduce the contact area of adhesive/ink particles, improve the efficiency of adhesive/ink penetration through the screen, optimize printing resolution, and achieve high resolution and high difficulty printing.

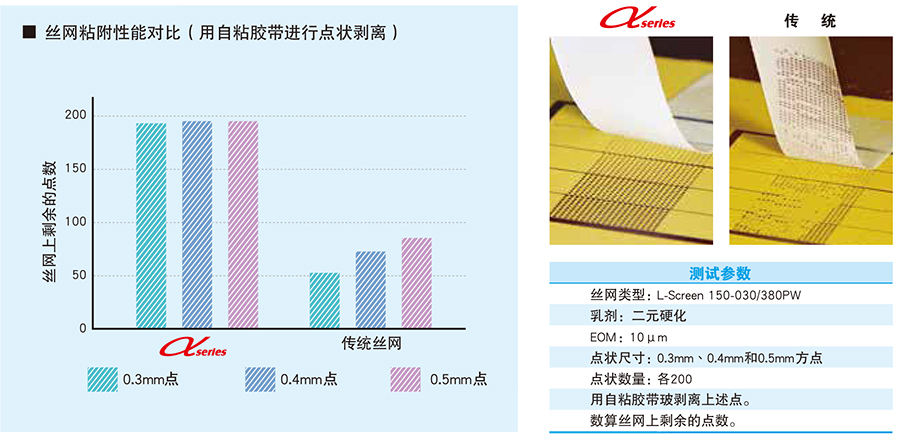

The surface of the silk screen treated with NEW SUPERI can maintain the tension of the emulsion/capillary membrane and extend the service life of the silk screen. This is especially true in long-term printing or when printing with abrasive ink. The adhesion performance of the silk screen has been proven through comparative testing with self-adhesive tape.

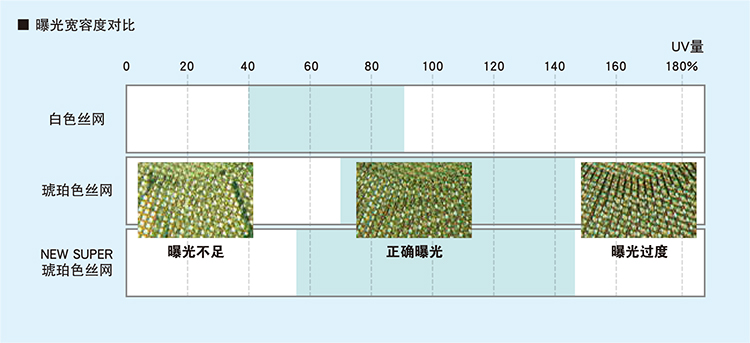

NEW SUPER treatment not only improves the adhesion of emulsion/capillary membranes; It also extends the exposure tolerance limit (under exposure), making it particularly suitable for attention to detail applications and in conjunction with CTS systems.

NBC α The series of high modulus polyester fiber mesh has been further improved through the best heat treatment process and strict quality control system, thereby minimizing the loss of mesh tension after stretching and printing treatment.

Hotline:0769 - 82866932

Hotline:0769 - 82866932

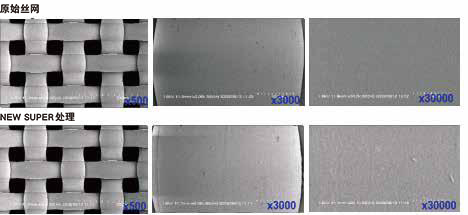

NEW SUPER treatment is a unique chemical and atmospheric plasma treatment (corona treatment) method for NBC, which changes the subtle surface roughness and microstructure.

1.Smoother adhesive/ink transfer

The surface of the screen that has undergone sub micron level trimming can reduce the contact area of adhesive/ink particles, improve the efficiency of adhesive/ink penetration through the screen, optimize printing resolution, and achieve high resolution and high difficulty printing.

2.Extend the service life of the silk screen

The surface of the silk screen treated with NEW SUPERI can maintain the tension of the emulsion/capillary membrane and extend the service life of the silk screen. This is especially true in long-term printing or when printing with abrasive ink. The adhesion performance of the silk screen has been proven through comparative testing with self-adhesive tape, as shown in the photo below.

3.Expand exposure tolerance

NEW SUPER treatment not only improves the adhesion of emulsion/capillary membranes; It also extends the exposure tolerance limit (under exposure), making it particularly suitable for attention to detail applications and in conjunction with CTS systems. The following figure shows a comparison of exposure tolerance for three different types of silk screens.

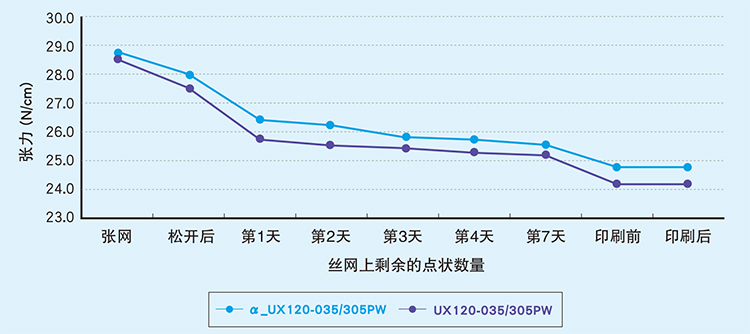

1.Minimize tension loss

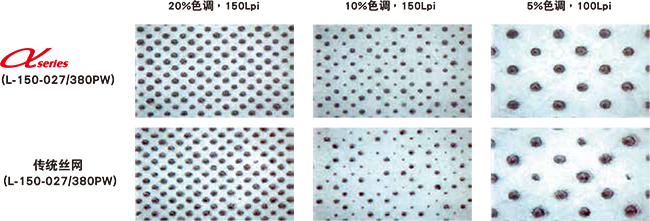

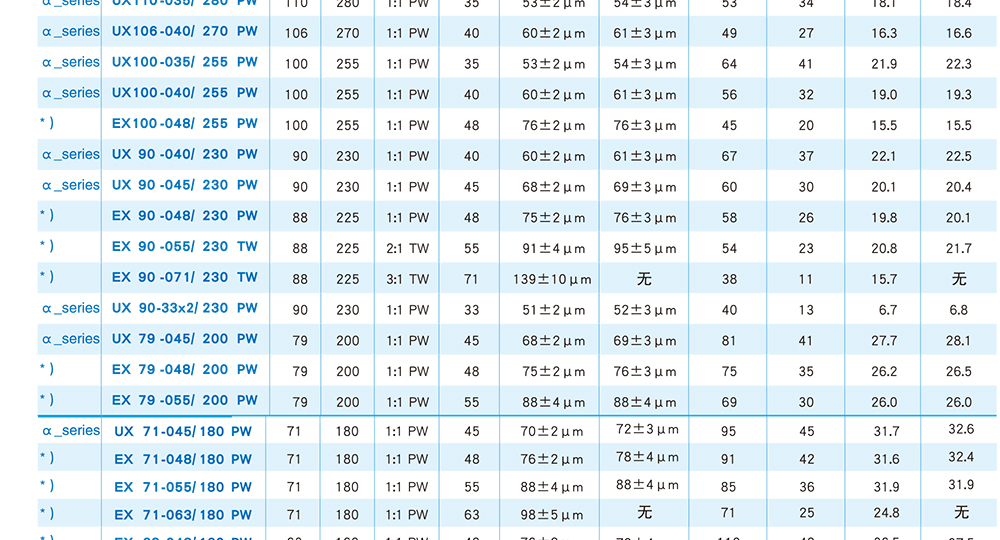

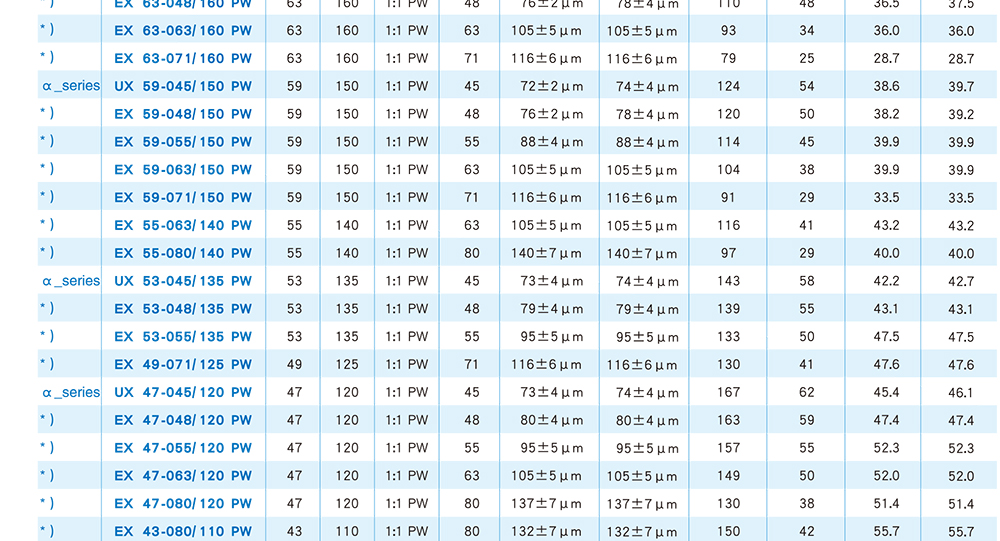

NBC α The series of high modulus polyester fiber mesh has been further improved through the best heat treatment process and strict quality control system, thereby minimizing the loss of mesh tension after stretching and printing treatment. Introduction to the following figure α Comparison of tension loss between series and original specifications of silk screens.

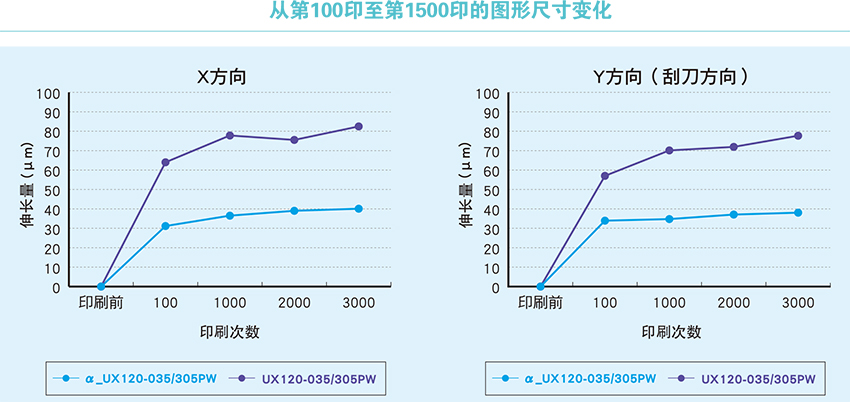

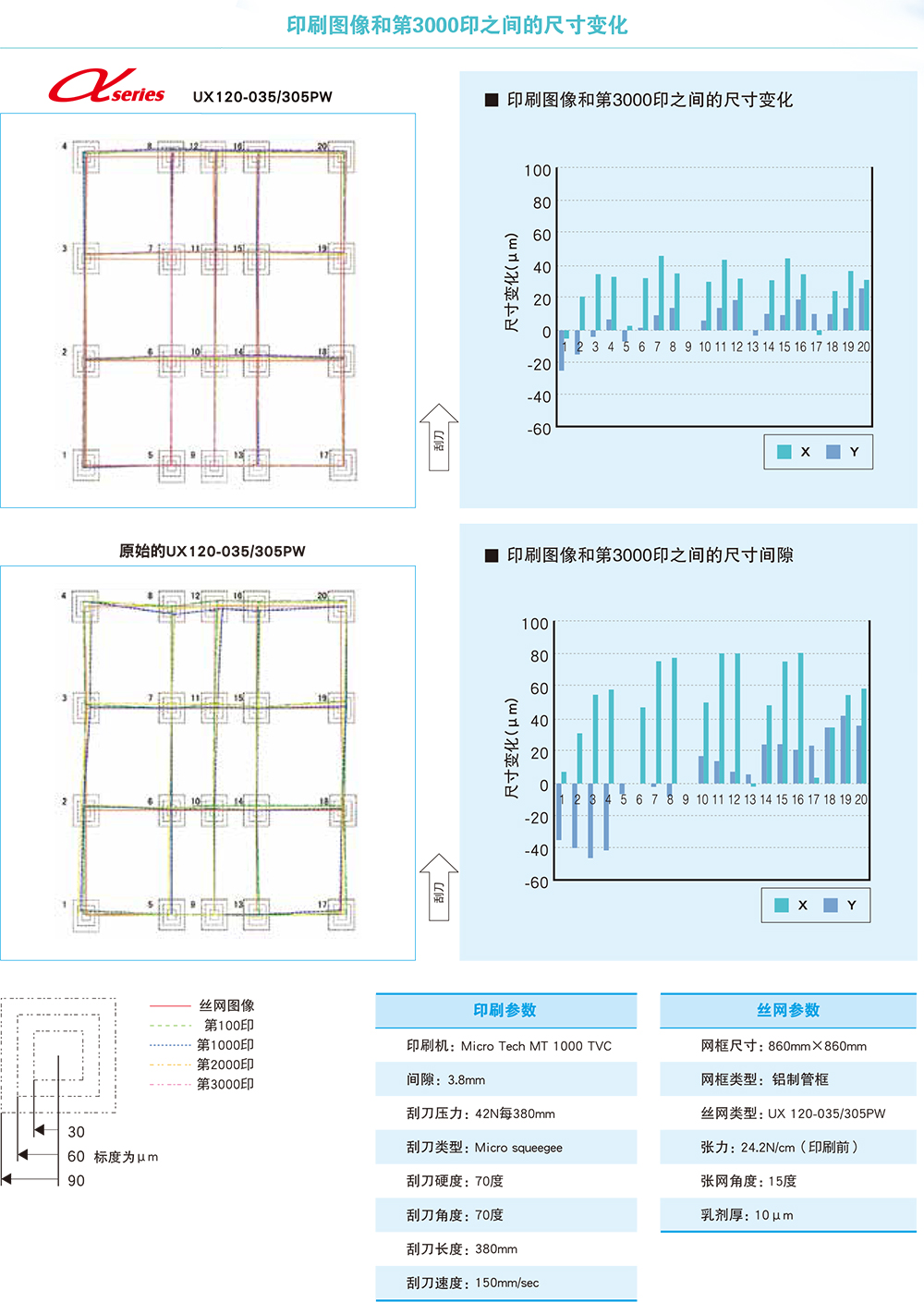

2.Further improve printing size accuracy

The following figure is a comparison table of graphic size changes (elongation) between printing dimensions (300mm x 300mm) and printing results, proving that α The dimensional accuracy of UX120-035/305PW has been significantly improved in long-term printing.

Previous item:None

Next item:NL&AS-SCREEN