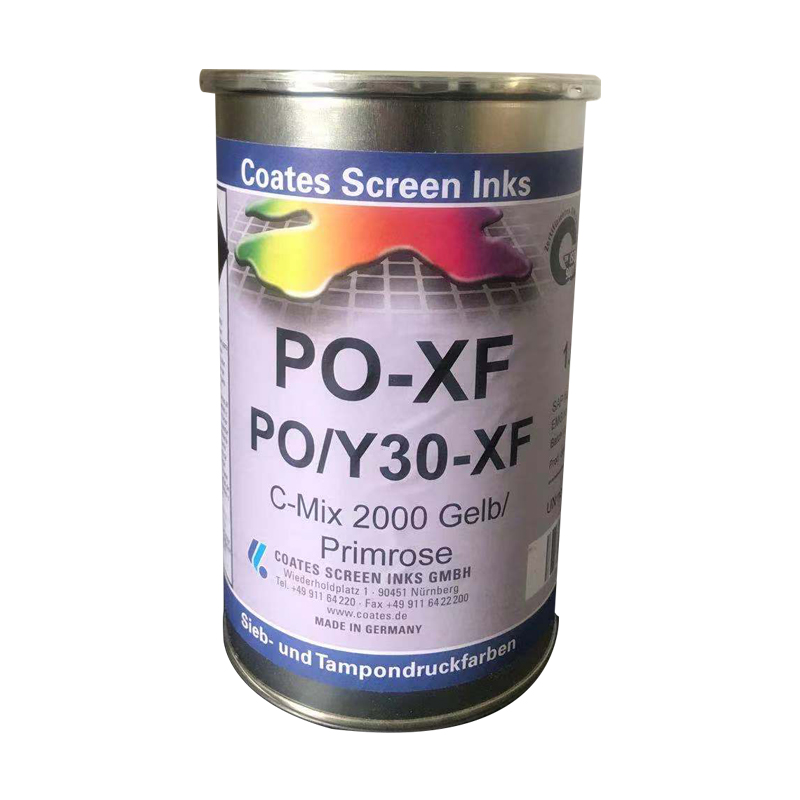

- Product details

- Service hotline:0769 - 87727302

Ink type

Single and two-component screen printing ink.

Use to

Suitable for the following materials: pre treated polyethylene, polypropylene; For various metals, coatings, wood, and paper.

Appearance

The ink layer has high gloss and good transparency.

Performance

After adding a hardener, the physical properties of the ink layer are better, such as water resistance and solubility.

Special advantages

The weather resistance of the ink can reach 7-8 levels, and it has excellent adhesion to oxygen electrodes and drawn parts. As a single component ink, the evaporation and drying speed is fast.

Drying time

Metal class: 150 ℃ for 30 minutes; Plastic, paper, wood, etc. should be stored at 60-80 ℃ for 30 minutes, and their physical properties should be tested after being left for 24 hours.

Mixing ratio

PO-XF can be used as a single component ink or as a two-component ink with the addition of 10% ZH hardener (yellow color, short usage time) or ZH/N/00 hardener (lighter color than ZH).

Solvent

Use VD20, VD60, and VZ25 as diluents, with an addition amount not exceeding 20%.

Note

As a two-component ink, the usage time is approximately 6-8 hours; If the color is metallic, the usage time will be reduced.

Plate washing

Use URS, URS3, or VD40 as cleaning agents

Previous item:None

Next item:TP 300 Series